![]() November 01, 2022

November 01, 2022

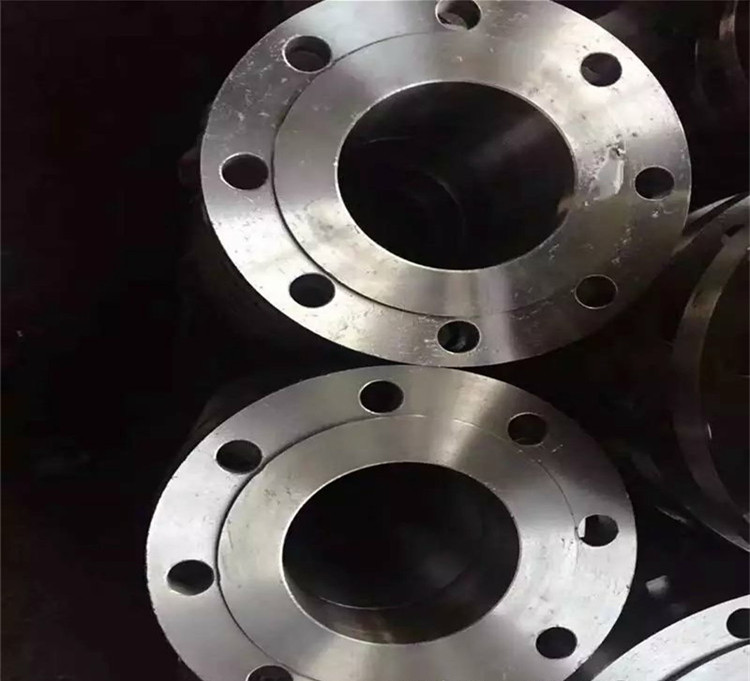

Summary Of Forged Flanges

Finer Forged Flanges is the flange products with the best mechanical properties of a product, its raw materials are generally tube billet, and then cut and then continuously beat, in order to eliminate the segregation, loose and other defects in the ingot. The price and mechanical properties are higher than the ordinary casting flange a grade. Finer Forged Flanges is the pipe and pipe and valve connected with each other parts, connected to the pipe end; Also used in the inlet and outlet of the equipment flange, used for the connection between two equipment is to make the pipe and pipe connected to each other parts, connected to the pipe end. It is an accessory product of pipeline. The main materials of Low Cost Forged Flanges are carbon steel, alloy steel and stainless steel. The main standards are national standard, electric standard, American standard, German standard, Japanese standard and so on. The main anti-corrosion treatments are oil coating and galvanizing. Forged Flange has good pressure and temperature resistance, and is generally suitable for high pressure and high temperature working environment.

The High Quality Forged Flanges process generally consists of the following steps: selecting the high quality billet for blanking, heating, forming and cooling after forging. The forging processes include free forging, die forging and membrane forging. Production, according to the size of forging quality, the number of production batch choose different forging methods.

Free Finer Forged Flanges productivity is low, processing allowance is large, but the tool is simple, versatility is large, so it is widely used in forging simple shape of single, small batch production forgings. The free forging equipment includes air hammer, steam-air hammer and hydraulic press, which are suitable for the production of small, medium and large forgings. Die forging has high productivity, simple operation, easy to realize mechanization and automation. The die forging has high dimensional accuracy, small machining allowance and more reasonable fiber distribution, which can further improve the service life of the parts.

The above is the Summary Of Forged Flanges we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

Send Inquiry